The enemy of screw and barrel efficiency is wear. Screw wear is a result of the flow of plastics against the screw and barrel as well as metal contact between the flights and barrel. Extruder screw and barrel wear is a serious matter for maintenance and engineering departments in plastics and rubber processing industries. At Wellex, we offer full-service wear solutions to barrels, or cylinders, screws and other plasticizing components for single screw extruders and twin screw extruders in plastics industry.

Base materials for screws and barrels:

Nitriding Steel and Alloy Steel

GB 38CrMoAlA JIS SCM645 Wr.Nr. 1.8509 DIN 41CrAlNi7 Nitralloy 135M

GB 42CrMo JIS SCM440 Wr.Nr. 1.7225 DIN 42CrMo4 AISI 4140

Böhler V820 Wr.Nr. 1.8550 DIN 34CrAlNi7

DIN 31CrMoV9 Wr.Nr. 1.8519

AISI 4340

Tool Steel:

JIS SKD61 Wr.Nr. 1.2344 DIN X40CrMoV5-1 AISI H13 Böhler W302 ISOBLOC

JIS SKD11 Wr.Nr. 1.2379 DIN X155CrVMo121 AISI D2 Böhler K110

Powder metallurgy-HIP methods (hot isostatic pressing)

Böhler M390, Vanadis 8, Vanadis 10, Vanadis 23

CMP 9V, CMP 10V

Stainless Steel:

Stainless Steel 304 Wr.Nr. 1.4301 DIN X5CrNi18-10

Stainless Steel 316 Wr.Nr. 1.4401 DIN X5CrNiMo17-12-2

17-4 PH Stainless Steel Wr.Nr. 1.4542 DIN X5CrNiCuNb16-4 AISI 630

X35CrMo17 stainless steel Wr.Nr. 1.4122 DIN X39CrMo17-1

Super Alloys:

Hastelloy C-276

Inconel 625

Inconel 718

Heat treatments:

Gas Nitriding Plasma Nitriding(Ion Nitriding) Through-Hardening(vaccum hardening)

Quenching and tempering, gas/ion nitriding and additional hard facings (bimetallic coatings) can be incorporated.

Coatings:

Hard Chrome Plating

Flight OD Carbide Encapsulation

Full Tungsten Carbide Coating(Carbide encapsulation)

PVD Coating

Nitrided screws and barrels

Screws and barrels for standard applications made of nitriding steel. High surface hardness can be achieved by the choice of nitriding steel after 120 hours’ gas nitriding to increase the service life of the screw and barrel.

Applications Recommended: pipes, tubes and profiles with low filler contents. Low protection against wear.

Hardened & nitrided screws and barrels

Screws and barrels made of high quality hot working steel. The screws and barrels are hardened and then nitrided for maximum hardening depth. There is a higher surface hardness with good corrosion resistance can be achieved through the choice of base material compared to nitriding steel.

Applications Recommended: window profiles with high titanium dioxide content, pipes with higher filler contents or regranulates. profiles with abrasive fillers.

Nitrided and armoured screws , tungsten carbide bimetallic barrels

A combination of armoured screw and tungsten carbide bimetallic barrel for maximum wear protection. By selecting the right filler material, a particularly well-matched friction pairing can be achieved. The outer diameter of the screw is thus protected against high abrasion wear.

Applications Recommended: vinyl sheet flooring products (LVT), window profiles with regenerated granulates as well as extrudates with abrasive fillers.

Armoured & tungsten carbide coated screws, tungsten carbide bimetallic barrels

A combination of armoured screw and tungsten carbide bimetallic barrel for maximum wear protection. By choosing the right hardfacing material, a particularly well-matched friction pairing can be achieved. The flight surface of the screw is thus protected against high abrasion wear. In addition, maximum wear protection is achieved on the screw flank and core. The tungsten carbide coating can be used over the entire screw length or only in certain areas.

Applications Recommended: wood plastic compounds, extrudates with a very high content of abrasive fillers, the extrusion of pencils.

To help resist wear, Wellex makes screws more wear resistant through hard facing.

Wear resistant screw hard facing alloys

wear-resistant Stellite cobalt-base hard facing alloys and weld overlays:

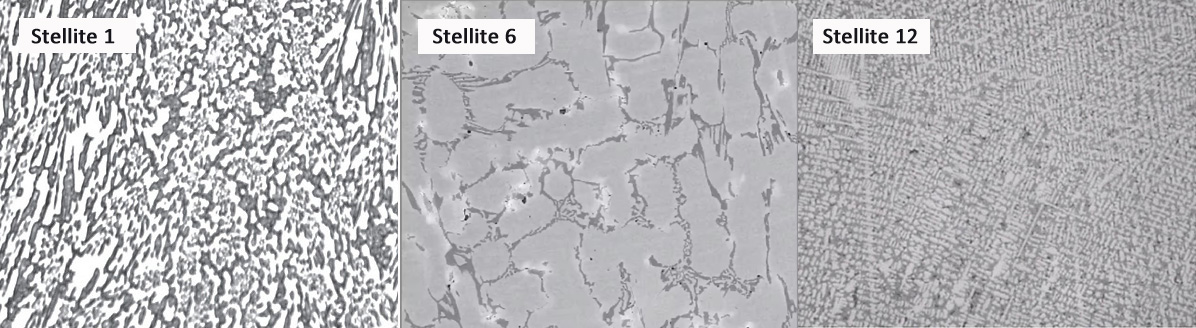

Stellite cobalt-base alloys consist of complex carbides in an alloy matrix. They are resistant to wear, galling and corrosion and retain these properties at high temperatures.

Stellite 1 Hardness: 50-58 HRC

Stellite 6 Hardness: 36-45 HRC

Stellite 12 Hardness: 45-51 HRC

wear-resistant Colmonoy nickel-base hard facing alloys and weld overlays:

Colmonoy 56

nickel-base hard facing alloy with chromium

Hardness: 53-58 HRC

Specifically designed for rebuilding and making new plastics extrusion screws using plasma transferred arc (PTA) application. High levels of chromium and carbon produce large populations of chromium carbides for superior abrasion and corrosion resistance. The optimized PTA formulation also has reduced boron and increased silicon for better weldability and puddle control.

Colmonoy 57

nickel-base hard facing alloy with chromium and tungsten

Hardness: 52-57 HRC

Specifically formulated for overlaying the flights of new and rebuilt extrusion screws, food processing industry feed screws.

Colmonoy 83

nickel-base hard facing alloy with tungsten carbide

Hardness: 45-55 HRC

A tough nickel-chromium-tungsten-boron matrix alloy containing chromium carbides with the addition of extremely hard tungsten-carbide particles for excellent abrasive wear protection. Excellent edge retention. Specifically for plasma transferred arc (PTA) application.

Colmonoy 88

nickel-base hard facing alloy with chromium and tungsten

Hardness: 59-64 HRC

Unique alloy containing chromium and tungsten borides and carbides for maximum abrasion and corrosion resistance for high-temperature, highly abrasive applications.

Wellex bore-lining alloys for centrifugally cast bimetallic cylinders or bimetallic barrels with high wear resistant performance

WLX122 Fe-boron base alloy: iron-boron alloys or iron base alloys with rich nickel and boron

with high abrasion resistance and thermal stability

For unfilled or lightly mineral filled(less than 30%) general purpose applications in medium abrasive and corrosive process environments.

Close to: Xaloy X-102, Wexco 666, Reiloy R121, Bernex A110

WLX216 nickel-chromium Fe-boron base alloy: iron-boron alloys with higher content of chromium and nickel for corrosion resistance

to achieve better resistance to abrasion and corrosion

for processing mineral filled plastics with glass fiber up to 40%

Close to: Xaloy X-220, Wexco 686XL, Bernex AC333, Reiloy R131

WLX356: nickel-cobalt base alloy: highly corrosion resistant Ni-Co matrix alloy with thermally stable tungsten carbides

outstanding resistance to both abrasive and corrosive wear

Ideal for processing polyvinyl chloride resins, and other resins containing corrosive flame retardants, volatile additives, etc.

Close to: Xaloy X-306, Wexco 555, Bernex C242, Reiloy R215

WLX666 tungsten carbide alloy: nickel matrix alloys with uniformly dispersed thermally stable micro tungsten carbide particles at a high percentage level

maximum resistance to extreme abrasive and corrosive wear

widely used in highly corrosive processing environments, such as plastics with flame retardants, blowing agents, highly corrosive resins containing halogens and fluoropolymers (FEP, PFA, ETFE and PVDF, etc.)

Close to: Xaloy X-800, Wexco 777-Durocast, Bernex ACW800, Reiloy R216

Key words: cilindro bimetallico e vite in satellite, viti di estrusione stellitate,