Counter-rotating twin-screw extruders are used mainly for processing PVC products, such as pipe, profile, sheet, pellets and film. The conical twin screws and barrels are widely used in the extrusion of PVC pipes, PVC profiles and PVC pelletizing.

Twin screws are divided in parallel and conical configurations.

Counter-rotating twin screw extruders have two screws that spin in the opposite direction. Also often intermeshing this style of machine is usually found in the profile, PVC or wood composite industry.

These machines typically have a much lower screw rpm and generally have much smaller L/D ratios. The screw direction allows for less shear than a single or co rotating machine.

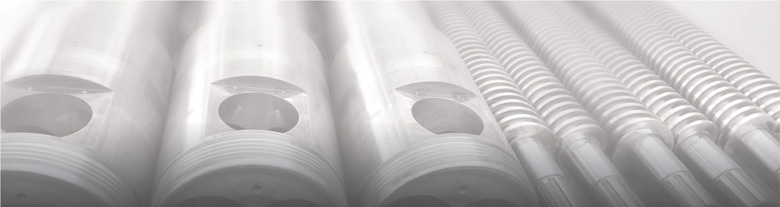

The two styles of machines within the counter-rotating extruder category known as parallel twin screw extruder and conical twin screw extruder. A parallel twin screw has a consistent barrel diameter through the entire barrel. A conical twin screw extruder has a taper. The feed section is much larger than the end of the barrel. Both counter rotating machines with often have barrel venting. The barrels and screws of these machines are not modular so they may need to be changed for your specific application.

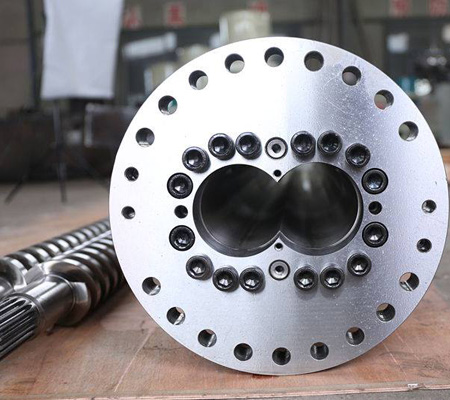

Conical twin screws and barrels, cylinders

Specifications:

24/52, 35/76, 45/90, 45/100, 50/105, 51/105, 55/110, 55/113, 55/120, 58/124, 60/125, 65/120, 65/132, 68/143, 70/135, 70/140, 75/150, 80/143, 80/156, 92/188, 105/213, 110/220, etc.

Base Materials:

Alloy Steel: 4140 steel(AISI 4140), SAE 4140, Nitralloy 135M, GB 38CrMoAlA, JIS SACM645, BS EN41B, 34CrAlNi7(1.8550), DIN 1.8509, DIN 1.8550, 41CrAlMo7, or equivalents.

Stainless Steel: 304, 316, 416, 17-4PH

Tool Steel: D-2, H-13, DC53, CPM 9V, CPM 10V

High Nickel Alloys: Hastelloy C-276, Inconel 625, Inconel 718

Flight Hardfacing Materials:

Nickel base: Colmonoy #56, Colmonoy #57, Colmonoy #83, Colmonoy #88

Cobalt base: Stellite #6, Stellite #12

Surface Hardenings:

Gas nitriding and Ion nitriding, Chrome plating, Carbide encapsulating, PVD coating, etc.

Nitriding Time: 120 hours Nitriding hardness: 1000Hv Nitriding thickness: 0.6-0.65mm

Machine Makes: Beier, Jwell, Liansu, Amut, Cincinnati Extrusion, Milacron, Battenfield-Cincinnati, Cincinnati Extrusion, Krauss Maffei, Milacron, Mikrosan, Weber, etc.

Extruder Models:

Standard Chinese Extruder Models: SJZ65/132, SJZ80/156, SJZ45/90, SJZ50/105, SJZ51/105, SJZ55/110, SJZ80/173, SJZ92/188; SJSZ 45/90, SJSZ 45/100, SJSZ 65/132, SJSZ 80/156, SJSZ 35/80, SJSZ 45/90, SJSZ50/105, SJSZ 51/105, SJSZ 55/110, SJSZ 80/173, SJSZ 92/188

Cincinnati Extrusion: CM45(45/90), CM55(55/110), CM65(65/132), CM80(80/156), etc.

Cincinnati Milacron/ Cincinnati Titan 45(45/90), Cincinnati Titan 58(58/124), Cincinnati Titan 68(68/146.5), Cincinnati Titan 80(80/174), etc.

Beier: SJZ51(51/105), SJZ55(55/110), SJZ65(65/132), SJZ80(80/156), SJZ92(92/188), SJZ105(105/216), etc.

Jwell: SJZ45/100, SJZ51/105, SJZ55/110, SJZ65/132, SJZ80/156, SJZ92/188, etc.

Liansu: LSE45/97, LSE55/110, LSE65/132, LSE80/156, LSE80/172, LSE92/188, LSE95/191, etc.

Theysohn: CON 40 (40/85), CON 50 (50/108), CON 63 (63/130), CON 68 (68/141)

Krauss Maffei: KMD 2-25 KK, KMD 2-40 KK (40/82.5), KMD 2-50 KK (50/103), KMD 2-60 KK (60/125), KMD 2-60 KK

Battenfeld: BEX 2-54 C, BEX 2-72 C, BEX 2-42 CC

American Maplan: DSK 62, CON 40, BEX 2-54 C

Battenfeld Cincinnati: conEX 38, conEX 63, conEX 72; conEX NG 42, conEX NG 54, conEX NG 65; fiberEX 38, fiberEX 50, fiberEX 72

Key words: cilindri bivite, estrusore bivite controrotante a viti coniche, coppie di viti controrotanti coniche,

extrusión doble husillo cónico, cámaras de extrusión doble husillo cónico, husillos de extrusión cónicos,

cámaras bimetálicas, cámaras nitruración, husillos nitruración, husillos bimetálicos, etc.