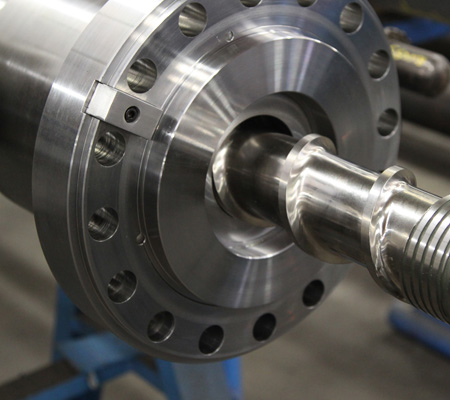

extrusion screws, barrels and grooved bushings

Plastic materials have broad variations in viscosity, melting points, volatiles, densities, moisture, sensitivity to shear, abrasive contaminants, etc. All of these variables, alone or in combination present significant barriers to maintaining homogeneity and melt consistency and output. So selecting the right extrusion feed screw design for your process is critically important to optimizing melt conditions and maximizing your material properties.

We can help you choose the optimal extrusion screw design for your process. From single-stage general purpose to two-stage barrier designs to double vented and with a host of mixer technologies and wear-resistant alloys, we have what you need to maximize your process. We have everything from low work to high work screw designs that work to keep your resins in proper condition.

Processes: blown film and cast film, compounding, extrusion blow molding, extrusion coating and lamination, fiber extrusion, medical tubing, pipes and profiles extrusion, plastics reclaim and pelletizing, sheets and tubing extrusion, wire and cable extrusion, silicone and rubber, etc.

Material: ABS, HDPE, LDPE, LLDPE, MDPE, PET, PLA, PP, PA, PC, PS, PBT, PBA, PPO, PPS, TPE, TPO, nylons, engineering plastics, fluoroplymers, FEP, MFA, PFA, PVDF, ETFE, etc.

Common base materials:

GB 38CrMoAlA, JIS SACM645, JIS SKD61, DC53

AISI 4140 HT, AISI 4340 HT, Nitralloy 135m, 300 and 400 series Stainless Steel, 17-4PH and 15-5PH , CPM-10V, Hastelloy, Duranickel and Incoloy

Hard facings: flame hardening, Tungsten Carbide alloys, Standards Colmonoy 56 and 83, Stellite Alloy

Screw types: metering screw, mixing screw, barrier screw.

Mixer Type: straight maddock (dispersive), spiral maddock (dispersive), pins, distributive mixer, blisters (fluted), saxton, dulmage, etc.

Film extruder makes(blown film and cast film):

Alpha Marathon, Bandera, Carnevalli, Davis Standard, FKI(Fong Kee International), Hosokawa Alpine, Jinming, Kabra ExtrusionTechnik, Kung Hsing, Lung Meng, Macchi, Macro Engineering, Polystar, Rajoo, Reifenhäuser, Rodofeli, Rulli Standard, Tecom, Windmöller & Hölscher (W&H), Windsor.

screws, barrels and feed throat for grooved feed extruders, smooth bore extruders

Complete plasticising system is tailor-made to the specific application

High throughput and broad processing range

Smooth bore or grooved feed barrel design

Keywords: tornillos y camisas para extrusoras, componentes extrusora plastico, camisa y tornillo para extrusora, Reparación y fabricación de conjuntos de extrusión, camisa y tornillo, punta válvula y asiento de inyección; máquinas para la industria plástica. componentes de la extrusora, extrusoras, cabezales, tornillos y camisas, fabricación y mantenimiento

extrusión monohusillo, cámaras de extrusión, husillos de extrusión, cuerpos alimentación, casquillos alimentación, etc.

cámaras bimetálicas, cámaras nitruración, husillos nitruración, husillos bimetálicos, etc.

estrusione, viti per estrusione, cilindri, viti, cilindri per estrusione, viti di estrusione stellitate, viti con profilo speciale, viti nuove con puntali (complete), cilindri monovite,

Шнековые пары, редукторы